Ferro Silicon Powder Rau Steelmaking minerals metallurgy

Siv

(1)ferrosilicon hmoov yog ib qho tseem ceeb ntawm metallurgical raw khoom, dav siv hauv casting, steel manufacturing, aluminium alloy manufacturing thiab lwm yam kev lag luam. Ferrosilicon hmoov tuaj yeem siv los ua tus neeg saib xyuas kom txo tau cov oxides hauv metallurgical furnaces, yog li tau txais cov hlau ntshiab.

(2)ferrosilicon hmoov kuj tuaj yeem siv los npaj ntau yam casting alloys. Hauv kev tsim steel, ferrosilicon hmoov tuaj yeem siv los ua desulfurizer kom tshem tawm sulfide hauv cov hlau, yog li txhim kho cov hlau zoo. Hauv kev tsim khoom ntawm aluminium alloys, ferrosilicon hmoov tuaj yeem siv los ua ib qho ntxiv los txhim kho lub zog thiab hardness ntawm aluminium alloys.

(3) ferrosilicon hmoov kuj tau siv dav hauv tshuaj thiab hluav taws xob. Hauv kev lag luam tshuaj, ferrosilicon hmoov tuaj yeem siv los tsim cov tshuaj organosilicone, siloxanes thiab silanes. Hauv kev lag luam hluav taws xob, ferrosilicon hmoov tuaj yeem siv los npaj cov khoom siv semiconductor, lub hnub ci hlwb thiab lwm yam.

Cov yam ntxwv thiab kev siv ntawm ferrosilicon hmoov

1. High purity thiab stability

Los ntawm cov txheej txheem kev npaj zoo, ferrosilicon hmoov tuaj yeem ua tiav cov kev xav tau purity siab, yog li ua kom nws ruaj khov hauv ntau yam kev siv. Qhov no high-purity ferrosilicon hmoov tuaj yeem muab cov khoom siv txhim khu kev qha kom tau raws li cov khoom siv siab ntawm kev lag luam sib txawv.

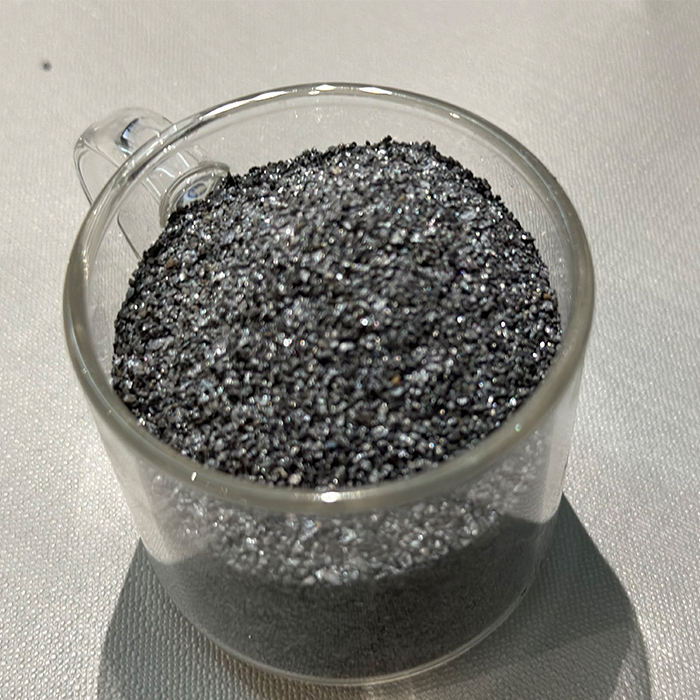

2. Uniform particle loj nrog zoo fluidity

Qhov loj me me ntawm ferrosilicon hmoov tuaj yeem tswj tau raws li cov kev xav tau tshwj xeeb, txhawm rau ua kom tau raws li cov kev xav tau ntawm kev lag luam sib txawv rau qhov loj me. Cov khoom me me me me thiab cov dej ntws zoo ua rau cov hmoov ferrosilicon yooj yim rau kev sib xyaw thiab cov txheej txheem hauv cov txheej txheem tsim khoom, thiab txhim kho kev tsim khoom.

3. Zoo heev sib nqus permeability

Vim muaj kev ua tau zoo ntawm ferrosilicon alloy hauv cov khoom sib nqus, ferrosilicon hmoov yog siv dav hauv cov khoom siv hluav taws xob xws li motors, transformers thiab inductors. Qhov sib nqus permeability ntawm ferrosilicon hmoov tuaj yeem txhim kho kev ua haujlwm thiab kev ua haujlwm ntawm cov khoom siv hluav taws xob, txhim kho kev siv hluav taws xob thiab txo kev siv hluav taws xob.

4. Zoo hnav tsis kam thiab corrosion kuj

Ferrosilicon hmoov tuaj yeem txhim kho qhov hnav tsis kam ntawm cov khoom siv, yog li ncua kev pabcuam lub neej ntawm cov khoom siv. Nyob rau tib lub sijhawm, kev tiv thaiv corrosion ntawm ferrosilicon hmoov ua rau nws tseem muaj peev xwm tswj tau qhov kev ua tau zoo hauv qhov chaw hnyav, thiab haum rau ntau yam tshwj xeeb.

Ntxiv nrog rau cov yam ntxwv saum toj no, ferrosilicon hmoov kuj tseem muaj cov coefficient qis ntawm thermal expansion thiab zoo heev conductivity. Qhov no tso cai rau cov hmoov ferrosilicon nyob ruaj khov ntawm qhov kub thiab txias thiab ua kom muaj cua sov zoo. Yog li ntawd, ferrosilicon hmoov yog dav siv nyob rau hauv lub tshav pob ntawm superalloy npaj thiab thermal tswj.

Chemical element

| Yam khoom% | Si | P | S | C | AI |

| ≤ | |||||

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.15 | 1 |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.15 | 0.5 |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.1 | 0.1 |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.05 Nws | 0.05 Nws |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.02 ib | 0.02 ib |

| FeSi72 | 72 | 0.03 ib | 0.02 ib | 0.15 | 1 |

| FeSi72 | 72 | 0.03 ib | 0.02 ib | 0.15 | 0.5 |

Daim ntawv ceeb toom: Kev tsim cov khoom sib txawv ntawm silicon calcium alloy raws li cov neeg siv khoom xav tau