Zoo Zoo Ferro Silicon particle rau Casting

siv

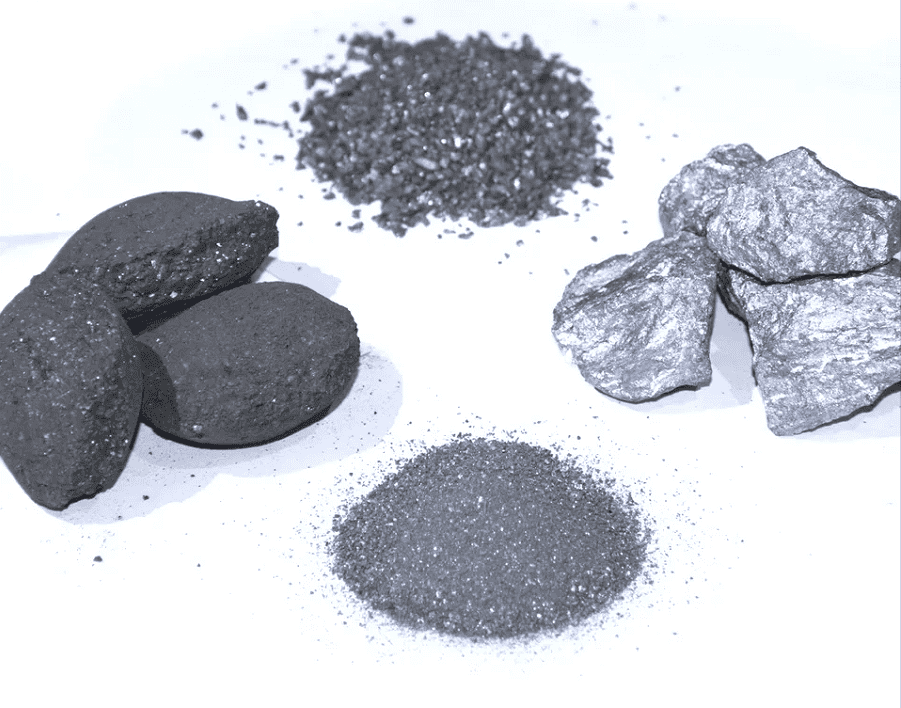

(1) Ferro silicon hais tsis tau tsuas yog siv nyob rau hauv steelmaking kev lag luam, tab sis kuj yog ib tug nquag siv metallurgical khoom nyob rau hauv lub cam khwb cia hlau kev lag luam. Qhov no feem ntau yog vim ferro silicon hais tuaj yeem siv los ntawm cov tuam txhab cam khwb cia hlau los hloov inoculants thiab spheroidizers. Hauv kev lag luam cam khwb cia hlau, tus nqi ntawm ferro silicon hais yog qis dua li cov hlau thiab lawv yooj yim dua melted, ua rau lawv cov khoom zoo cam khwb cia hlau alloy. Cov khoom zoo ferro silicon particle inoculant nrog cov khoom me me thiab cov nyhuv inoculation zoo thaum lub sij hawm casting tuaj yeem txhawb graphite nag lossis daus thiab spheroidization, ua rau nws yog ib qho khoom siv hlau tsim nyog rau kev tsim cov hlau.

(2) Siv ua deoxidizer thiab alloying tus neeg sawv cev hauv kev lag luam steelmaking. Cov tshuaj affinity ntawm silicon thiab oxygen yog loj heev, yog li ferro silicon hais yog muaj zog deoxidizers nyob rau hauv steelmaking rau nag lossis daus thiab diffusion deoxidation. Hauv kev lag luam steelmaking, nws feem ntau yog siv los ua tus neeg sawv cev ingot cap cua sov los txhim kho qhov zoo thiab rov qab los ntawm ingot los ntawm kev siv cov yam ntxwv uas ferrosilicon nplej tuaj yeem tso tawm ntau cov cua sov los ntawm ene hlawv ntawm qhov kub thiab txias.

Ferro Silicon particle rau stainless hlau ntau lawm

1. Tus nqi qis thiab yooj yim rau yaj

ferro silicon hais tsis tau tsuas yog siv nyob rau hauv steelmaking kev lag luam tab sis kuj nyob rau hauv lub cam khwb cia hlau kev lag luam feem ntau siv metallurgical cov ntaub ntawv, feem ntau vim hais tias ferro silicon hais yuav siv tau los ntawm cam khwb cia hlau manufacturers es tsis txhob ntawm inoculants thiab nodulators, nyob rau hauv lub cam khwb cia hlau kev lag luam, tus nqi. ntawm ferro silicon hais yog qis dua cov hlau, thiab yooj yim dua melted, yog cov khoom ferroalloy nrog lub peev xwm casting.

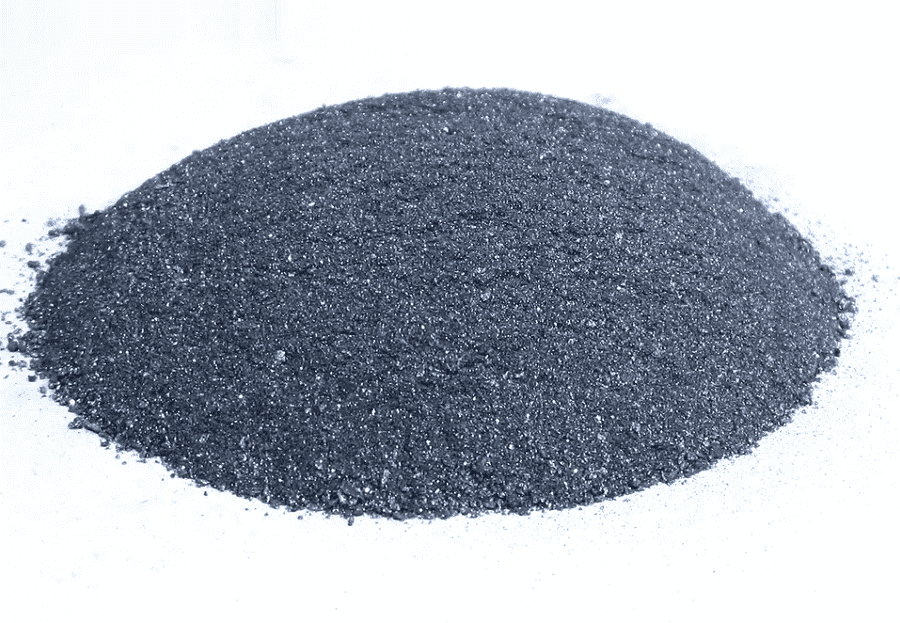

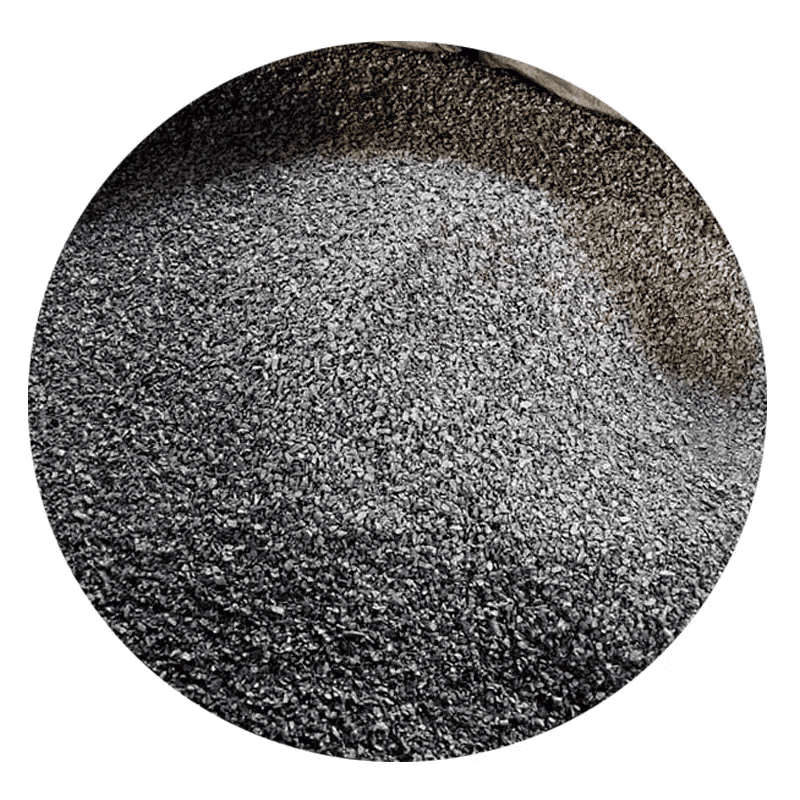

2. Uniform particle loj

Ferro Silicon hais tsis muaj hmoov zoo, ruaj khov inoculation nyhuv, thiab ib tug me me nyiam los tsim slag. Qhov hnyav tshaj plaws yog tias lawv muaj cov yam ntxwv ntawm lwm cov inoculants thiab muaj cov nqi qis dua.

3. Zoo elasticity thiab plasticity

Nws qhov elasticity tsawg yog vim nws qhov kev ua haujlwm qis qis, thiab nws lub zog tensile yog ob peb zaug siab dua li cov khoom siv hlau me me. Lub ferro silicon particle kuj muaj kev tiv thaiv corrosion zoo heev, thiab nws cov txheej txheej tiv thaiv tuaj yeem tiv thaiv qhov corrosion ntawm qhov casting.

4. Zoo machinability

Ferro silicon hais muaj cov cuab yeej ua haujlwm zoo, tuaj yeem ua tiav cov haujlwm ua haujlwm sai, thiab muaj kev ruaj ntseg zoo thiab hnav tsis kam, nrog rau kev ua haujlwm ntev. Qhov ntawd yog hais tias, ferro silicon hais muaj cov khoom siv zoo thiab yuav luag tsis muaj cov khoom seem, uas ua rau lawv zoo tagnrho cov khoom siv rau kev lag luam casting.

5. Cov khoom siv thermoplastic zoo heev

Ferro silicon hais muaj cov khoom siv thermoplastic zoo heev, tuaj yeem tiv taus deformation nyob rau hauv ntau qhov kub thiab txias, thiab tuaj yeem tswj lawv lub zog ntawm qhov kub siab dua, ua rau lawv tshwj xeeb tshaj yog siv rau hauv kev tsim cov thermoplastic castings.

Chemical element

| Yam khoom% | Si | P | S | C | AI |

| ≤ | |||||

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.15 | 1 |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.15 | 0.5 |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.1 | 0.1 |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.05 Nws | 0.05 Nws |

| FeSi75 | 75 | 0.03 ib | 0.02 ib | 0.02 ib | 0.02 ib |

| FeSi72 | 72 | 0.03 ib | 0.02 ib | 0.15 | 1 |

| FeSi72 | 72 | 0.03 ib | 0.02 ib | 0.15 | 0.5 |

Daim ntawv ceeb toom: Kev tsim cov khoom sib txawv ntawm silicon calcium alloy raws li cov neeg siv khoom xav tau